The Role of ASTM Standards in Ensuring the Quality of PVC Tiles

ASTM StandardsIn manufacturing PVC tiles, adherence to established standards is crucial for ensuring quality and reliability. ASTM International, formerly the American Society for Testing and Materials, provides these standards. This article explores various ASTM standards relevant to PVC tiles and their significance in assuring quality. ASTM standards are the backbone for ensuring the quality and safety of various materials, including PVC tiles. These standards define the procedures and criteria for testing and evaluating material properties, assuring manufacturers and consumers of the product’s reliability and performance.

ASTM Standards and Their Significance in PVC Tile Manufacturing

ASTM D638 – Tensile Strength

In-Depth Description: ASTM Standards D638 is a critical test for evaluating the tensile strength of plastic materials, including PVC. This test involves applying a stretching force to a PVC sample until it reaches the breaking point, thereby measuring its ability to withstand tensile stress.

Role in Quality Assurance: Tensile strength ensures that PVC tiles can endure the stress and strains of daily use, particularly in high-traffic areas. It is a crucial indicator of the tile’s durability and long-term performance.

ASTM D2047 – Slip Resistance

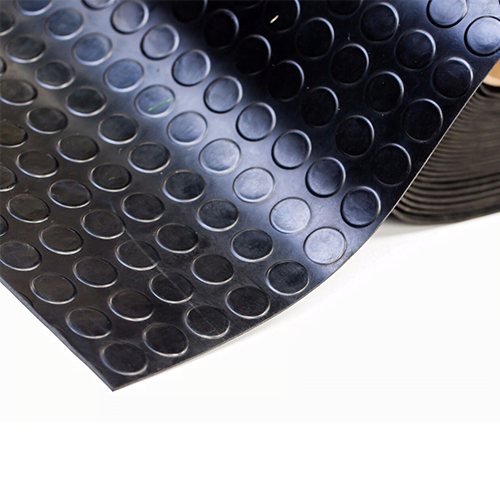

Detailed Analysis: This standard provides a method to measure the slip resistance of floor surfaces, a critical safety aspect. It helps assess how effectively a floor surface can prevent slipping, a common hazard in public and private spaces.

Importance in Application: Ensuring slip resistance is especially crucial in public areas, workplaces, and homes where safety is a priority. This standard helps in mitigating the risk of accidents due to slipping.

ASTM E648 – Critical Radiant Flux

Comprehensive Description: This test measures the flame spread rate and smoke development of flooring materials. It assesses how a material reacts to fire, precisely the speed at which flames spread and the volume of smoke produced.

Relevance for Fire Safety: This standard is essential in evaluating the fire safety of PVC tiles. It ensures that the flooring material doesn’t contribute significantly to fire spread and produces minimal smoke, both crucial for safety during a fire incident.

ASTM D2859 – Flammability

- In-Depth Exploration: Known as the ‘Steiner Tunnel Test’, this standard assesses the flammability of floor coverings. It measures how flooring materials behave under direct flame exposure.

- Relevance to PVC Tiles: Though primarily designed for carpets, the principles of this test apply to PVC tiles. It evaluates their burning behaviour and the potential to contribute to fire hazards, ensuring enhanced safety in environments where fire risk is a concern.

ASTM F1700 – Solid Vinyl Floor Tile

Extensive Description: This specification covers solid vinyl floor tiles, detailing the requirements for their physical properties, dimensions, and performance characteristics.

Quality Assurance Role: Adherence to ASTM F1700 ensures that PVC tiles meet rigorous size, durability, and overall performance criteria. This standard is a cornerstone in the manufacturing process, ensuring consistency and reliability in the final product.

Conclusion

ASTM standards play a pivotal role in the quality assurance of PVC tiles. From tensile strength to slip resistance and fire safety, these standards provide a comprehensive framework for evaluating the performance and safety of PVC tiles. For manufacturers like Camp Manufacturing, adhering to these standards is a commitment to delivering high-quality, durable, and safe products to consumers. As the industry evolves, these standards will continue to be essential in maintaining the quality and reliability of PVC flooring solutions.

Frequently Asked Questions (FAQs)

1. How does Camp Manufacturing ensure the tensile strength of its PVC tiles according to ASTM D638?

At Camp Manufacturig, we rigorously test our PVC tiles for tensile strength in compliance with ASTM Standards D638. This involves subjecting our tiles to controlled stretching forces until they break. These tests help us ensure that our PVC tiles are durable and can withstand the mechanical stresses they are likely to encounter, especially in high-traffic areas.

2. What measures does Camp Manufacturing take to comply with ASTM D2047 for slip resistance in PVC tiles?

We prioritise safety by ensuring our PVC tiles meet the slip resistance standards set by ASTM D2047. This involves testing the surface of our tiles to measure their traction and prevent slip-and-fall accidents. These tests are crucial for maintaining the safety of our products, especially in environments prone to moisture where slip hazards are higher.

3. Can Camp Manufacturing’s PVC tiles meet the critical radiant flux requirements of ASTM E648?

Absolutely. Our PVC tiles are designed and tested to meet the critical radiant flux requirements as outlined in ASTM E648. We conduct flame spread and smoke development tests to ensure our products align with fire safety standards, making them suitable for use in various environments where fire safety is crucial.

4. How do Camp Manufacturing’s PVC tiles adhere to the flammability standards of ASTM D2859?

Camp Manufacturing adheres to ASTM D2859 standards by ensuring our PVC tiles undergo the ‘Steiner Tunnel Test’. This test evaluates the flammability of our tiles, assessing their burning behaviour under direct flame exposure. Our compliance with these standards is a testament to our commitment to producing safe and reliable flooring solutions.

5. Does Camp Manufacturing follow ASTM F1700 specifications for its vinyl floor tiles?

We strictly follow ASTM F1700 specifications in producing our solid vinyl floor tiles. This includes meeting the set criteria for the tiles’ dimensions, physical properties, and performance characteristics. By adhering to these specifications, we guarantee that our PVC tiles are of consistent quality, offering durability and high performance to our customers.